Do you want a narrower lifting sling without sacrificing strength and durability?

Riggers come across this scenario constantly: they have a great synthetic lifting sling, but it’s too wide to fit in a trunnion, or other constricted lifting points, creating unnecessary downtime for workers.

Thankfully, Slingmax® has a new product out: the Helix™ High-Performance Synthetic Roundsling. And even though their patented Twin-Path® sling is one of the best synthetic lifting slings on the market, they are simply too wide for certain applications.

We understand that investing in a new lifting sling can be a tough choice to make.

Thankfully, Mazzella has been a proud Slingmax manufacturing dealer for years now—with three manufacturing facilities in Cleveland, Granite City, and Virginia Beach—and we want to help you find the right Slingmax product for your application. Our article will cover all there is to know about the new Helix Roundsling, including:

What Is the Helix Roundsling?

Designed by Slingmax Rigging Solutions, the Helix Sling is an all-new synthetic fiber, high-performance roundsling.

Like other Slingmax products, such as the Twin-Path sling, the Helix Sling Core is made from K-Spec® yarn, an incredibly durable, strong, yet light weight material that is three times stronger than nylon or polyester fibers.

Additionally, the outer protective jacket of the Helix sling is made from braided HMPE fiber, offering riggers and operators excellent abrasion and chemical resistance, protecting the internal load bearing core fibers —making it a great fit for a wide range of industries and work environments.

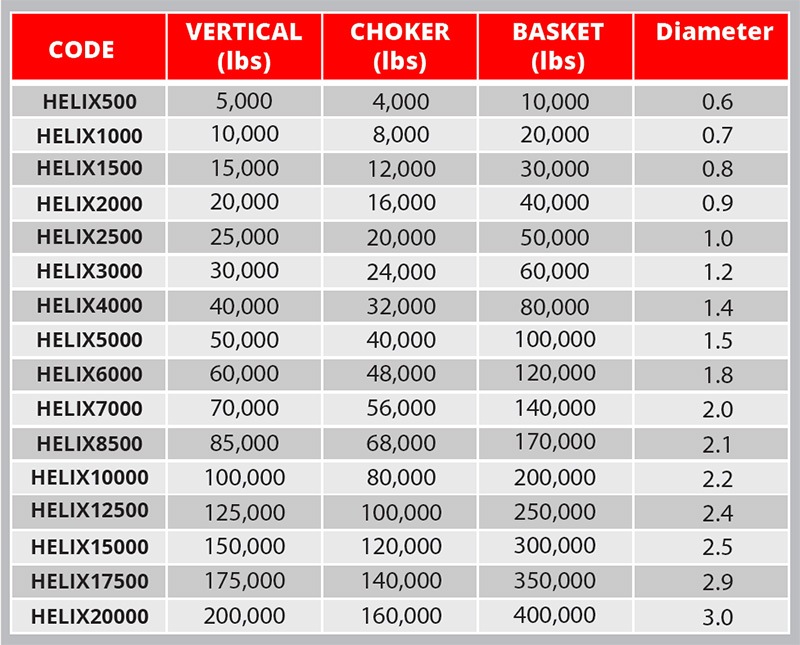

Helix slings are currently available in a vertical rated capacity up to 200,000 lbs., but Slingmax is working on increasing catalog capacities. If you do need to go beyond that, then you would probably have to switch to a Twin Path Sling, where the capacities go up to 800,000 lbs.

The Helix slings can be used in any hitch configuration: vertical, basket, and choker.

What are the Benefits of a Helix Roundsling?

A Smaller Profile

One of the biggest benefits of a Helix Roundsling is its smaller profile and narrow diameter. With the ability to fit into narrower lifting points, it eliminates the need for extra hardware and makes the rigging process simpler and more efficient.

This new design opens the door for synthetic roundslings to be used in applications that were once impossible.

Rifled Cover® Technology

The braided HMPE Helix jacket features Rifled Cover Technology, a patented technology which allows for an increased strength-to-weight ratio. It also allows for repeatability in the manufacturing process.

Rifled Cover Technology helically twists the core fiber during the fabrication process, increasing the strength of load bearing core fibers by 17%.

Fast Turn Around Time

All existing Slingmax dealers, like Mazzella, can make the Helix sling on their existing roundsling machines. So, even with very short notice, distributors can make a Helix sling to any length and capacity within a few hours.

Many Customization Offerings

One of the advantages of the Helix Sling is the vast number of customized solutions available to buyers.

They can be equipped with any of Slingmax’s cut or abrasion protection offerings, including the new Spider Sleeve (abrasion protection), or the CornerMax® Sleeve (cut protection).

They can even be constructed in an eye-and-eye configuration, where there’s an eye on each end of the sling with a jacket protecting the center. A maxi-jacket coating protects the Helix from abrasion.

What are the Best Applications for a Helix Roundsling?

Helix slings are ideal for any application where you have a constricted area to do your lifting, or the sling needs a smaller diameter to fit into more narrow hardware.

For example, if you have a trunnion on a load that was designed for wire rope, you can use a Helix, where other synthetic slings may not work. If you have a low headroom situation where a rope sling is going to be too long, the Helix becomes a great alternative.

What Industries Could Use Helix Roundslings?

Light weight, quick turnaround time, great for heavy lifts, multiple customization options—it’s no wonder the Helix can be used in so many applications and industries

They can be used in power generation plants and clean energy projects to lift heavy turbines and motors that are designed with constricted lifting points.

They can be used in construction to simplify rigging operations, remove larger shackles, and improve worker safety and efficiency.

You could also see Helix slings in general manufacturing and assembly line environments where repetitive rigging is common, and you want to keep things as simple and ergonomic as possible.

Helix slings are also great for marine applications because they are neutrally buoyant, so they won’t sink like a wire rope lifting sling would. The Helix sling is also completely unaffected by seawater. You could have it out in water for years, and the fiber will still hold strong.

How Does the Helix Compare to Other Lifting Slings?

If you’re looking at Helix slings compared to other roundslings on the market, they may appear to be very similar. But there are some key differences that are going to make the Helix a great choice.

When you look at your typical synthetic rope sling, there is no outer cover, leaving the load-bearing core yarns more exposed to the elements and to the load itself. As soon as you get any kind of abrasion or damage on the outside load-bearing fibers, you’ve compromised the sling and its rated capacity.

With the Helix sling, all of the load-bearing core yarns are protected underneath. So, if you have abrasion on the outside, you haven’t compromised the overall strength of the sling.

Since it is a roundsling, and you’re not constricted by splicing requirements, like a synthetic rope sling, Helix slings can be made to lengths as short as three feet. Helix slings are also made with small individual strands inside the load-bearing core yarns that give you a better D/d performance compared to a typical wire rope sling.

Additionally, the Helix is made with high-performance K-Spec core yarn, so it will stretch less than 1% under load—a similar rating to a wire rope lifting sling. You won’t see the kind of bouncing or shifting that you normally see with nylon or polyester slings.

What Best Practices Should You Follow for the Helix?

The best practices for a Helix sling are no different than any other synthetic lifting sling.

You will want to:

- Use fittings with no sharp edges

- Avoid dragging the sling on the ground

- Always use engineered cut or abrasion protection

- Avoid excessive heat environments

And just like other synthetic liftings sling, it would be smart to pair the Helix with some type of sling protection, including the new Spider Sleeve.

Are There Negatives to Using a Helix Roundsling?

One of the few negatives of a Helix sling is its lack of repairability. Unlike other Slingmax products, Helix’s have braided jackets that don’t have an area for a patch to be sewn on.

Helix’s also do not use the check fast inspection system that other Slingmax products carry.

And like any other synthetic lifting sling, Helix slings won’t be a great option in high-heat environments (anything above 180°F).

Where Can You Buy a Helix Roundsling?

It can be hard to determine if a new product is right for your organization. You may be happy with the lifting sling you already have. You may also may not want to take the risk of investing in a product that you know nothing about.

We hope this article cleared up some concerns you may have and laid out the best applications and use cases for the Helix sling.

Even though it’s a new product, the Helix is made with the same high-performance material and undergoes the thorough break test and qualities manufacturing processes that Slingmax has used for decades.

With three manufacturing locations, Mazzella is proud to be one of the largest Slingmax distributors in the country. Contact one of our team members today if you want to purchase a Helix sling for your organization. Furthermore, subscribe to the Lifting & Rigging Channel to see our upcoming collaborative videos with Slingmax.

Copyright 2024. Mazzella Companies.